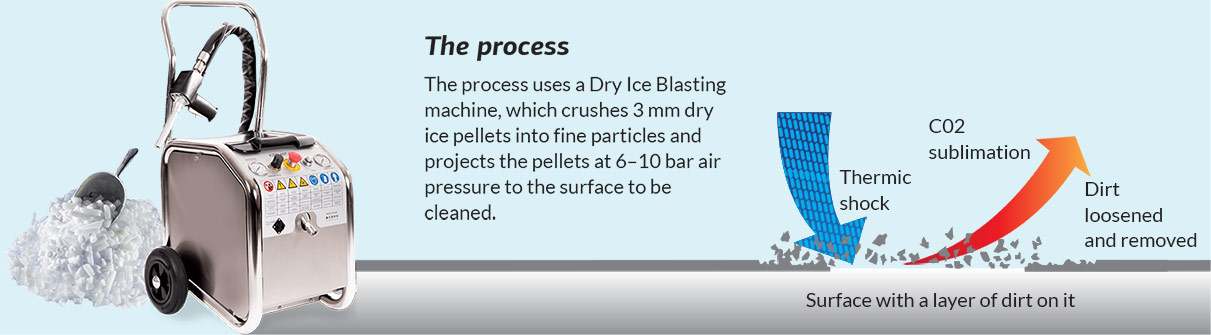

How dry ice blasting works?

-

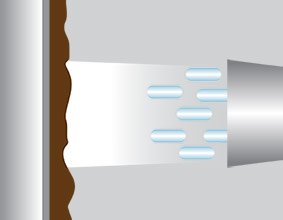

Pellets of Dry Ice are shot out of a jet nozzle using compressed air.

-

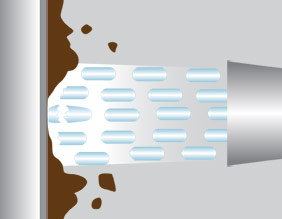

When blasted against the material to be removed, dry ice causes it to shrink and lose adhesion from its sub-surface.

-

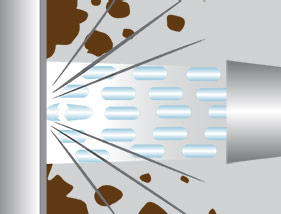

The warmer sub surface causes dry ice to convert back into CO2 gas and expand. This speeds up the cleaning.

-

After Dry Ice Blasting, the surface is clean and completely intact.

Benefits of Dry Ice Blasting

-

Non Abrasive

-

Superior Cleaning

-

Reduction of Plant Downtime

-

No Equipment Damage

-

No Waste Disposal

-

Non-hazardous

-

Sanitises the Surface

-

Cost Effective

-

Environmentally Safe

-

Supports Sustainability

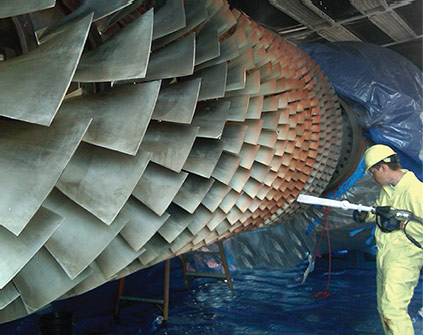

Types of Equipment that Dry Ice Blasting can Clean

-

Generator Stator-Rotor

-

Air Cooled Condenser

-

Printers

-

Turbine Rotors

-

Ducts

-

Conveyors and Chains

-

Heat Exchangers

-

Boilers

-

Food Processing Plant

-

Ovens

-

Tyre Industry

-

Grilles

-

Material Dry Ice Blasting Removes

Mould, Algae, Dirt/Dust, Soot/Carbon, Paint, Sugars/Syrups, Ink, Hydrocarbons, Pathogens/Bacteria, Adhesives/Resins, Manufacturing Residue, Cement/Blaster, Rust and Scale/Stains Tar and Bitumen, Expanded Foam

-

-